Summertime in the hot shop

July 2, 2022

It finally got warm in Washington this week, but it's been sweaty in the hot shop for months! What's a hot shop you ask? It's where glass comes alive! I've been working for Jim Flanagan, owner of Fremont Antique Glass Co. to learn more about turning a molten ball of glass into a sheet of unique colored glass for use in stained glass art. In my last newsletter I mentioned mouth blown glass. Jim is the one and only full time mouth blown glass sheet maker in the USA!

In glass terms, "antique" doesn't refer to age, it refers to the method of blowing glass in this traditional way.

Jim began blowing sheet glass about 40 years ago in the Fremont district of Seattle. Along with a small crew they built all of their kilns, furnaces and annealing ovens by hand; designing, welding, redesigning and refining as they went. If you have ever watched "Blown Away" you have some idea of how glass blowing can be both delicate and incredibly physical labor. It's well worth the effort.

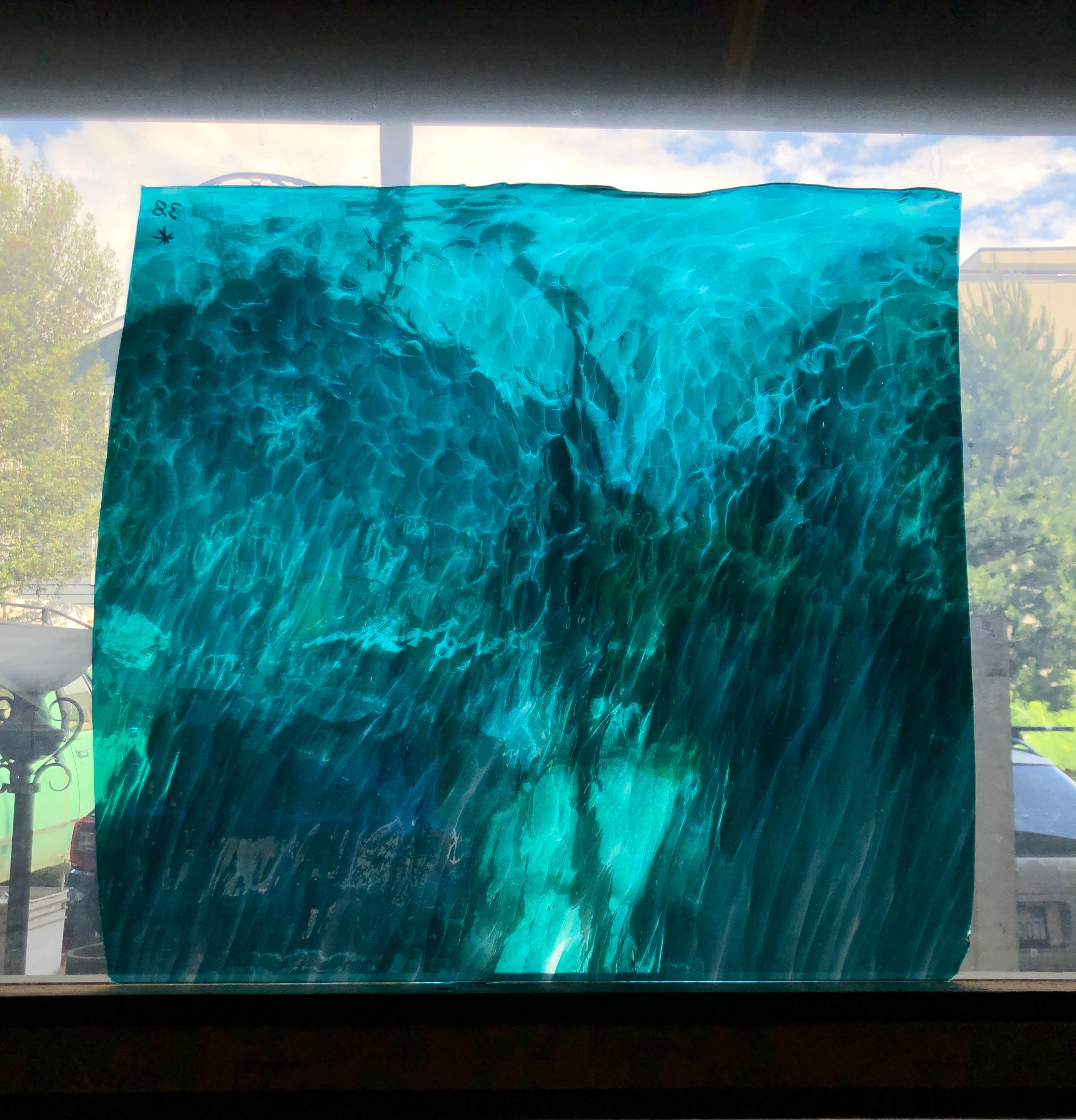

Mouth blown glass gives the creator full control over mixing colors, bubble patterns, streaks and reams (textures that give glass a whole heck of a lot of character!). The glass isn't always a perfect thickness, but that can result in a perfect light to dark shade in one sheet that may be exactly what I want for a mountain range!

Traditionally, all sheet glass was made by blowing a cylinder, cutting along the length then opening and flattening it. Now, most glass is mechanically made with automated ovens dumping molten glass onto a conveyor belt and rolling it out like a pasta in a continuous ribbon in uniform thickness and then quickly cooling it as it slides through an annealing oven. "Handmade" glass involves people ladling glass from a furnace onto a table, giving it a few mixes with a pitch fork and then sending it through a press and cooling oven. (If glass is cooled too quickly it becomes unstable and cracks.)Both of these mechanized methods leave the imprint of whatever surface the glass is spread onto. That surface may be intentionally surfaced to create a ripple pattern in the glass, but it also - no matter how smooth- reduces the clarity and luminosity of the glass. Mouthblown glass is never pushed against a hard surface in its molten stage so it retains the perfect silken smoothness on both sides.

I've simplified a few steps, but here is the full antique method of mouth blown sheet glass:

The first step is to gather molten glass onto the end of a pipe and roll it into a ball. Then a little air is blown into the pipe and more glass gathered on top of that. The ball is continually spun on the pipe because if not, it will droop and melt off. Colors are added by either rolling the ball in ground up colored glass (frit) or adding a solid heated chunk (bar) on top of the ball and spreading it evenly down around the ball of clear glass.

If a swirling mix of color is desired the color must be massaged, twisted and rolled onto the growing cylinder of hot glass. The cylinder is continually blown and stretched by gravity and rotation all while keeping it hot enough with repeated trips back into the glory hole- a gas fired furnace about 2200 degrees F, with an opening wide enough to accommodate the cylinder.

The tube is swung and also rolled up and down in a trough filled with small graphite spikes to give the glass streaky texture on its surface. These striations are what give the glass extra sparkle and it’s characteristic refraction when it casts a shadow. These lines are also what some people use to describe “antique” glass, though as I stated before, true antique glass is defined by being mouth-blown.

When the cylinder is finally at the perfect size and shape, a bit of clear class is added to the end and then the master gaffer heats it and blows on the pipe until the end pops open. Then that edge of clear glass is trimmed off and the sides are leveled between two cherry wood sticks while the gaffer continues to spin the pipe.

Once the cylinder is stable and cooled to the point that it is not flopping around, a tiny bit of water is applied at the junction with the pipe so it can be easily broken off into into an annealing oven for several hours of slowed cooling. Once cylinders have cooled, the top cone is cut off and about a 1/2 inch strip is cut out lengthwise. The cylinders are placed back into a rewarming kiln where they come up to about 900 degrees in preparation for flattening.

Prepared cylinders are put back into a different kiln that heats them up in preparation for flattening. Once hot enough the cylinder is placed into what looks like a pizza oven. Wet cherry wood sticks are used to encourage the cylinder to fall open and lay flat into a sheet. From the flattening oven the sheet is slipped onto a large wooden pizza spatula and into an annealing oven to cool. The next day it will be flipped to the other side into a different annealing oven and reflattened for evenness.

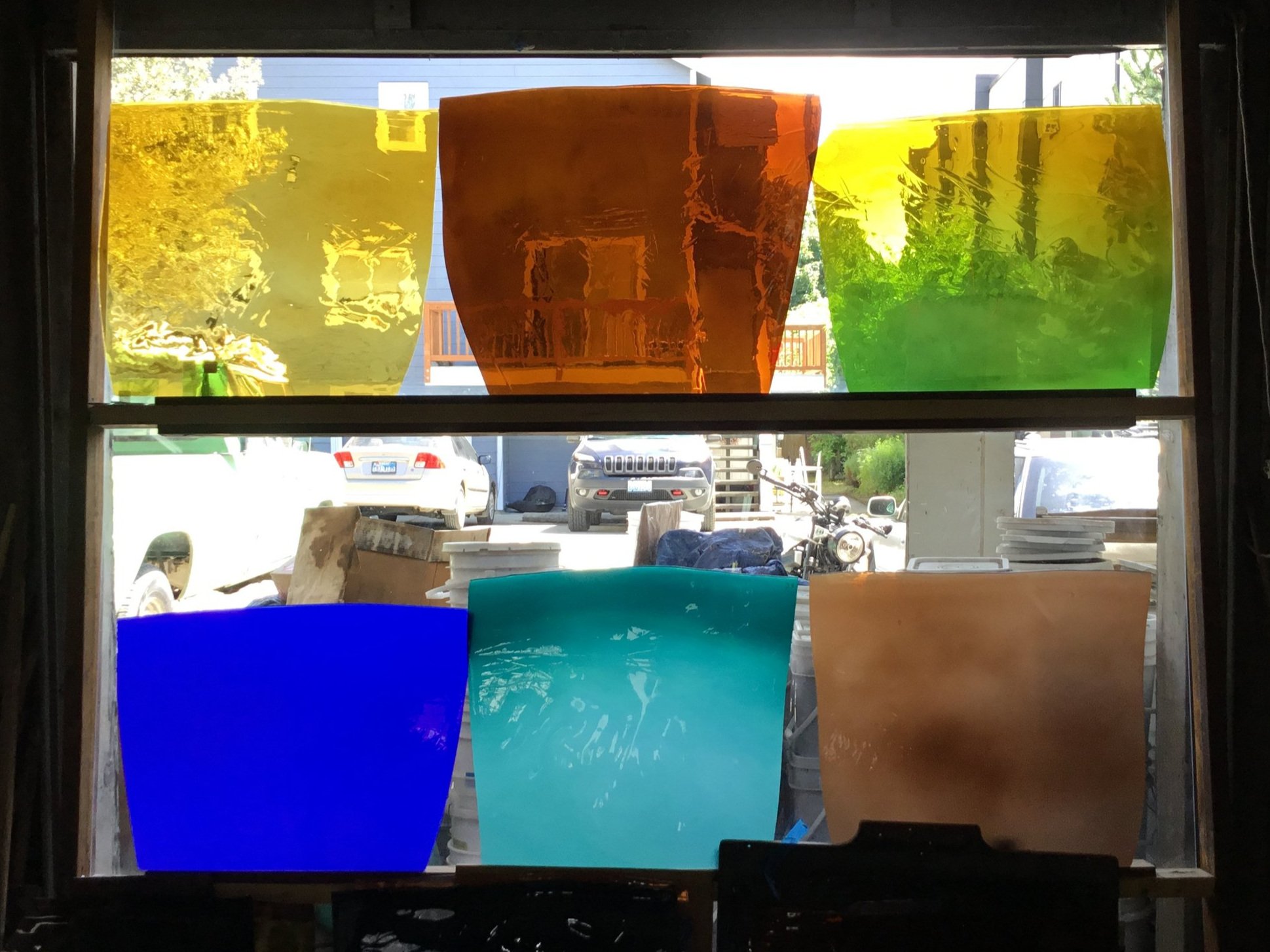

When a sheet comes out of the annealer it will be inspected for cracks, waves or any other defects. Then it will be cleaned and the the bottom arc cut off so it can be stacked upright. Finally these beautiful works of art are ready to be turned into different works of art in stained glass panels!